Blacksmith

Hammering away at metal bars are the blacksmiths. Using their strength and knowledge, they can put any flaming hot piece of steel into the shape they desire. The end result of the shaping differs from one blacksmith to another. Some turn it into everyday items, while others specialise in weaponry or armour.

Career

Qualifications

Strength is above all a most essential quality to have when it comes to blacksmithing. The steel will not shape itself after all. However, if one does not possess strength, there are ways around that. Especially the high elves and gnomes have found artificial ways to increase their strength just for blacksmithing by using machines of sorts.

Other than strength, blacksmiths are expected to have a keen eye. They have to check the ores and bars they receive for impurities and therefore make sure that the quality is up to par.

No prior education is required to become a blacksmiths. In most cases, the way to become a blacksmith is by becoming a master's apprentice. Depending on the master and the speed at which an apprentice learns, it can take anywhere between six months to five years before an apprentice can go out on their own.

Career Progression

Within blacksmithing, there are many ways and routes to advance ones career. However, first comes the apprenticeship at a master blacksmith. When an apprentice is finally released by their master, they can choose to start a practice themselves, or to join one to continue mastering the art.

Mastering the art of blacksmithing takes another couple of years. During these years, the journeyman usually tries the different flavours of the profession to figure out which one suits them best. Some of these routes require additional education or skills to even try. For instance, to become a weaponsmith, they expect the journeyman to have at least some experience with handling weapons. If the journeyman doesn't, it is up to the master to decide to give them a chance or not.

When the journeyman has finally reached the master levels of their craft, they can seek even further education and specialisation. There are different types of weapons, different types of armour and still a lot to learn. They can start teaching apprentices themselves, or travel the nation to learn even more techniques.

Payment & Reimbursement

Most blacksmiths are paid in coin. Depending on the quality of their work and the materials, the price can range greatly. Most smiths have a system in place that lets them calculate the price accordingly upon selling it to customers.

Sometimes, blackmiths offer their services for a reduced price. This is especially true for new shops trying to gain some customers. First, they have to show their quality of work, before a person might switch over to them. Another reason for a reduced price happens when a shop goes out of business and has to sell their wares as quickly as possible.

However, most smiths are rewarded appropriately for their work. Often it takes quite some time to create a custom piece for the commision. Finding the right materials for it, is also no easy feat. With all that added up, people are willing to pay a heafty price for true works of art or for high quality equipment.

Other Benefits

Aside from financial payment, there isn't much gain to get from the profession. It takes a truly new approach, technique, or material to become a noteworthy blacksmith.

While most dwarfs see it as a disgrace that they are not the famous blacksmiths, a few have sought her out to get to know her. They wanted to see who she was and, much to their surprise, this lighthearted and stubborn girl behaves just like a dwarf. She even shares her dislike, to lightly put it, towards high elves!

However, Ithethandrielle Zylleth has managed to make a name for herself in the blacksmithing community, to the dismay of the dwarfs. This little wood elf has revolutionised the way to incoorporate different materials into steel to strenghten armour plates and weapons which makes them almost indestructible.

Hey! Don't be silly! Call me Elle.

Perception

Social Status

The social status of a blacksmith varies greatly from one ethnicity to another. High Elves see everyone using their hands as inferior as they value the mind over everything else. Therefore, they see blacksmiths as low folk. It is also the reason why there aren't many within Yuran society.

For gnomes, blacksmiths are an essential part of the community. They can create the sprockets, gears and all other tinkerthingies that keeps their technology running. Since gnomes aren't very tall and strong to begin with, the ones that possess the qualities to become a master blacksmiths are almost revered. However, in most cases, these gnomish societies put in their order at dwarfish establishments, since they simply offer better and more consistent quality.

Within human and dwarven societies, becoming a blacksmith is an average job. It isn't looked down upon, but it also isn't praised unless one manages to become a true master and provide a most unique service or craft. Therefore, within these communities, the social status of the smith is partially tied to their quality of work and mastery of the art.

History

The Dwarfs were the very first of the races to understand and perform the duties of a blacksmith. Being born from the mountain, they had the most experience checking the quality of the materials, but also working in the heat of the forge as sweat drips away at their face. The clinging sound of hammers battering down the metal is music to their ears.

For a long time, dwarfs have kept the art of blacksmithing to themselves. It gave them an edge in the wars to come as they were able to produce the highest quality weaponry and armour that has led them to win many battles. However, a few dwarfs deflected from the <empire> as their viewpoints about the wars with other species began to clash. To give these other races a fighting chance, they taught them blacksmithing. It is one of the few key factors that turned the tide against the dwarfs and put the rest of the world on equal ground with them.

Peacetime

In recent years, with less conflict plaguing the four races, blacksmithing has evolved. It is not just bashing metal into shapes of destruction. Nowadays, they make tools for other professions, create parts for furniture, but also decorative items that people can place in their homes or in their hair. Within gnomish societies, blacksmithing surged when they got a knack for tinkering and required parts to put together their wild creations. Some even use the profession to create works of art. It has given rise to the Metal Sculptor who can create intricate designs using many smithing techniques in unconvential ways. The most famous sculptor goes by the artist name Ipaonosi. No one knows who they are, if they are dwarf, gnome, elf, human, or maybe even another race. However, what is known is that having one of their works in your home makes you a rich person. Not in value of money, but in value of the art.Operations

Tools

There are a few primary tool that every blacksmith uses in their workshop to do their work. They need a hammer, an anvil, a forge, and a waterbath. With those three components, a good blacksmith can do their work granted that they are given the right materials. However, as the skills of the smith improve, so does the equipment and the tools. For certain techniques, they have to use specialised tools to perform it correctly. Finally, there are the initial polishing tools they use to get the work somewhat smooth before turning it over to a Polisher or Sharpener for the finishing touches.

Since gnomes don't possess much strenght, some of them have tried to create a "smasher" that does the hammering for them. However, their invention isn't working out too well yet, as they have trouble calibrating the correct strength at which the hammer must be used. They continue to work on it and improve what they can by learning from the dwarfs.

Materials

The materials a blacksmith has at their disposal are a most vital ingredient to any work they do. It determines the quality of the commission before the smith has even touched it.

Blacksmith's primarily use ores or smelted bars. Dwarfish smiths obtain the latter from the The Dwarven Mining Enterprise. Others can get their hands on bars either from smelters or mining companies in their vicinity.

Workplace

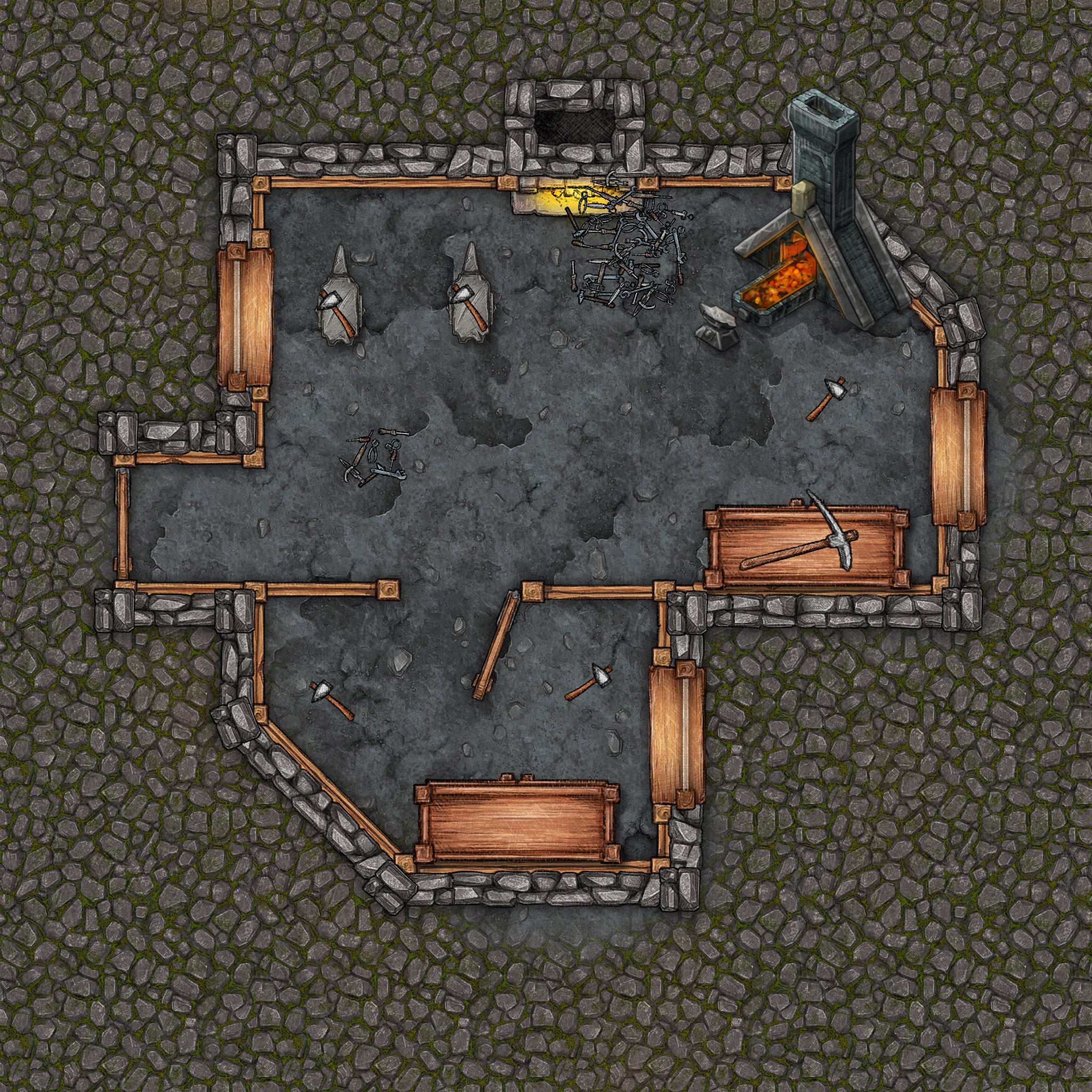

A blacksmith's shop is usually small with a master doing most of the work and, sometimes, one or two apprentrices or journeymen helping. Right in the middle or at the edge is a large forge where they melt the materials or heat them up to start the shaping.

Scattered across the space are all kinds of tools, but the hammer always lies predominantly on the anvil waiting to sing their song of clinging metal of metal. The apprentices usually try to keep the place somewhat tidy, but it isn't in the nature of most blacksmiths to put too much thought into it.

On the side of the shop, is usually a small storage room where the smiths keep their tools and their finished commissioned work until it is picked up.

Provided Services

Most blacksmiths provide many services when it comes to their profession. They can create items for you on commision, but they can also repair broken items in most cases.

In Irrean society, blacksmiths often get commissioned to create intricate design pieces to put in the The Dwarven Twists. For some blacksmiths, it has become their primary source for commissions. For others, it is a great way to get into blacksmithing and learn the ropes.

Dangers & Hazards

Working with forges and flaming hot pieces of metal is quite dangerous, to say the least. However, that has never stopped any smith from making silly mistakes. Common accidents that occur in the field are things like burning a body part. Literally any body part. Or setting ones beard on fire.

"Dranos, have you heard?" Gartari asked snickering.

"What are you talking about?" Dranos growled looking up annoyed from his newspaper.

"Darius..." The young dwarf could barely hold his laughter. "Darius burned his... his..."

Gartari burst out laughing as he pointed at his private parts. Dranos just shrugged.

"I warned that boy plenty times. A smiths workshop is no place for pranks. Looks like he finally got what he deserved.

"What are you talking about?" Dranos growled looking up annoyed from his newspaper.

"Darius..." The young dwarf could barely hold his laughter. "Darius burned his... his..."

Gartari burst out laughing as he pointed at his private parts. Dranos just shrugged.

"I warned that boy plenty times. A smiths workshop is no place for pranks. Looks like he finally got what he deserved.

Alternative Names

Smithy

Type

Artisan

Demand

Common

Famous in the Field

Other Associated professions

Ranks & Titles

Dwarfish Grooming Industry

The Dwarven Mining Enterprise

Even I don't understand why my goddamn father gave me this ridiculous name. He should have known better than to think that us wood elves would ever ben on the same level as those darned high elves.

Comments